The Vertical Disintegrator by Hosokawa Micron is a versatile machine offering an excellent solution for the efficient size reduction of many raw materials, easily coping with problematic materials such as wood, coal and grain, which always include a proportion of impure materials that require separating out from the pure processed product. Suitable for diverse industries – from food and beverage to rubber and chemicals – the reliable equipment is routinely used by Hosokawa Micron customers around the world, helping to produce everything from the finest malt whisky in Scotland to nutraceuticals in Norway. Its capacity to process specialist Aramid fibre helps to enable the manufacture of composite material and a huge number of high-performance products, such as PPE, safety equipment, bulletproof vests, golf clubs and tennis rackets, high-speed trains, luxury yachts, wind turbines and optical cables. Our popular Vertical Disintegrator is currently available in three models and can efficiently and uniformly reduce fine, course, wet, moist, dry, small to medium-size materials of around a hardness value of < 3 Mohs (including minerals such as limestone and marble).

The energy-efficient, practical Vertical Disintegrator complements the wide-ranging capabilities of the three companion Hosokawa Micron Disintegrator products – Angle, In-line and Horizontal.

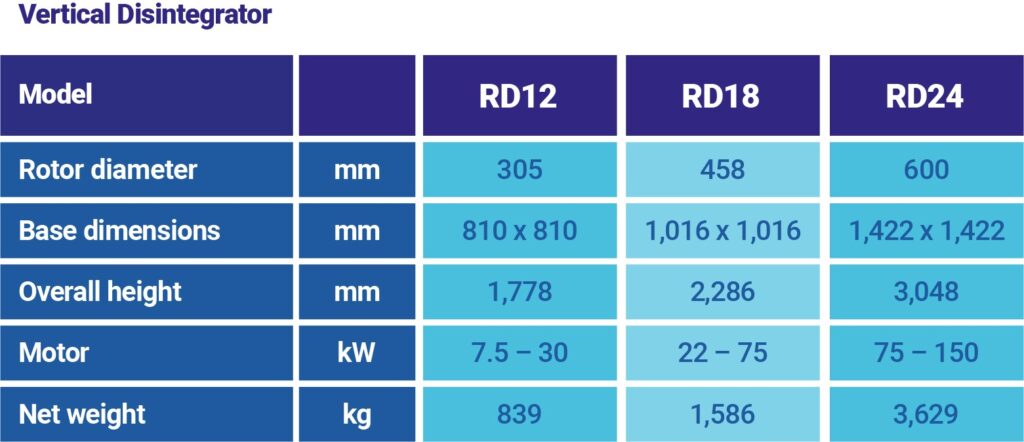

The Vertical Disintegrator is currently available in three models (RD12, RD18 and RD24) and is typically built from stainless steel and carbon. The equipment can easily be configured with a wide range of motor, perforated screen and rotor sizes to suit the demands of the material being processed. Typical throughput rates are determined by factors including the chosen configuration of the equipment and the material itself.

The smallest version (RD12) includes a 300mm diameter rotor and power options up to 30kw. Typically, this could process a material such as Mica flake slurry at a rate of two tonnes per hour.

At the other end of the scale, the RD24 is almost twice the size of the RD12 and comes with up to a 710mm diameter rotor and up to a 150kw drive. With a 600mm diameter rotor, 90kw drive and a perforated screen with 6mm holes, a challenging raw material such as seaweed could be processed at a rate of approximately 9 tonnes per hour using the Vertical Disintegrator.

The Vertical Disintegrator is easy to maintain and a CIP system can be integrated to make cleaning an easy and efficient process.

Hosokawa Micron Ltd has wide-ranging experience of designing, engineering and manufacturing bespoke Vertical Disintegrators that comply to the specific requirements of our customers. Along with single units, we are also able to produce multiple Vertical Disintegrators for customers as part of the same order, often manufacturing two identical pieces for delivery at the same time.

The Vertical Disintegrator is an impact mill used for grinding and classifying small to medium-size raw materials, including difficult-to-process products such as those with a high fat or moisture content. Its ability to effortlessly separate impure and pure material (of variable wetness and fineness levels), makes it a very practical option for manufacturing pharmaceuticals, composite materials, wallpaper and paper products, dietary supplements, chocolate and dyes, as well as processing fruits, vegetables, frozen meat, resin, fishmeal, tallow, seaweed, barley, mica flakes and petrochemicals.

Hosokawa Micron has developed a two-stage process system to meet the demands of pharma, food and drink, cosmetic, agrochemical and medical device manufacturers, who require freshly milled alginate (seaweed/marine algae). Products that contain alginate include nutritional supplements, colloidal wound dressings, cake mixes, sauces, beer, textile dye, waxed paper, slimming foods, confectionery, slow-release herbicides, shampoo, indigestion liquid and face creams.

The Vertical Disintegrator grinds straightforward materials, as well as potentially problematic raw materials that require proper consideration to process them efficiently. This could include materials with a high fat or moisture content, as well as products that will produce waste material, such as wood and grains.

Raw material is initially introduced into the Vertical Disintegrator from the top via a screw feeder and passes down into the processing chamber to be ground by the actions of the spinning rotor and a collection of hammers inside the chamber. The processing chamber includes a 360° perforated screen which vertically surrounds the grinding components, which work together to reduce the size of the material.

The material is kept in the chamber by the upper feed hammers and the lift hammers at the bottom, while the mid-section hammers assist with the dispersion and grinding. When the material has decreased in size sufficiently, it will pass through the perforated screen (also known as a primary discharge screen) and exit via the circumference of the disintegrator, passing through an outlet from where it is collected into a bag filler (for standard processing, this would normally be achieved by suction).

Impure material that has been rejected from the successfully processed product exits the disintegrator via a secondary outlet, which can be left open or closed depending on whether impure materials will be present in the processed product.

The 360° perforation screen includes a uniform series of holes, which are available in a range of sizes, depending on customer specification. This enables a uniformly processed end product size and helps to reduce the temperature of the processing material to ensure the quality of the end product is not compromised by the generated heat of the processing method.

In-Line Disintegrator – an Alternative Option

Hosokawa Micron’s In-line Disintegrator (RI model) works in a virtually identical way but has the option of gland packing or mechanical seals, making it more suitable for in-line production where paste, slurry and other liquid materials are being processed in a multi-component process system. Typically, material would enter a feed tank before being pumped into one side of the disintegrator, where it would be processed and exit on the opposite side where downstream processing would continue.

The Hosokawa Micron Vertical Disintegrator may be used as a standalone piece of equipment but may also be incorporated into a tailor-made process system for the processing of diverse, challenging materials.

For the milling of seaweed to make alginate, for example, we have developed a two-stage size reduction process system that firstly uses a Pre-breaker to initially break down the fibrous, gritty and slimy seaweed, followed by the Vertical Disintegrator, which ensures a uniform particle size reduction is achieved to enable efficient further processing of the material. High yield with less effluent is ensured by the integrated perforated vertical screen, which effortlessly expels products with a high moisture content at speed, using centrifugal forces to assist the process.

Hosokawa Micron Ltd has amassed decades of knowledge and experience creating the technology and equipment for the processing of easy and hard-to-process raw materials to make powders, pastes, sauces etc and process soft to hard materials – everything from slurry to metals. Our Vertical Disintegrator is just one of a range of disintegrators that form part of our wider product portfolio for processing and containment. Our experts would be pleased to provide advice and create a bespoke process system, incorporating a Vertical Disintegrator, to meet your specific application requirements.

Where a disintegrator and in-line processing are required, the Hosokawa Micron In-line Disintegrator (RI model) may be a better option. This equipment operates in an almost identical way to the Vertical Disintegrator, but has a gland packing or mechanical seal option that allows it to be installed between pipework.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on