Convenience, adaptability and energy-efficiency are just a few of the strengths possessed by the Multiprocessing System, a five-in-one mill and classifier capable of processing an enormous number of soft to hard materials into ultrafine powders, whether simple or challenging to handle.

Extremely popular for small-scale processing, improving existing products or processes and developing entirely new products where grinding properties may be unpredictable without extensive testing and refining, this veritable all-rounder comprises a compact main unit and a choice of five easily exchangeable milling and classification modules, based on five of Hosokawa Micron Group’s most popular industry-leading, production-scale products. Easy to clean, maintain, operate and adapt for different processing requirements, the sophisticated Multiprocessing System is available in a range of sizes and offers a huge amount of versatility and flexibility, along with highly accurate and easy scale-up when required, making it an extremely economical, capable and essential piece of equipment for constantly evolving product development.

The Multiprocessing System is used by a variety of industry sectors that utilise or make superfine powders and granules, but is particularly sought-after by pharmaceutical and food manufacturers, who benefit from tailor-made designs that meet their strict industry requirements – including ATEX and FDA certification and cGMP-standard features such as smooth surfaces, no dead spaces and easy dismantling for thorough emptying, cleaning and sterilisation of ‘product contact’ components in an autoclave. All product contact components are constructed from high-quality rust and acid-proof stainless-steel, while milling and classification components can be coated with wear-resistant ceramic to help protect product integrity and extend the working life of the Multiprocessing System.

To complement the Multiprocessing System, tailor-made containment equipment – such as isolators for processing and handling potentially hazardous and potent materials – can be designed, manufactured and supplied by Hosokawa Micron Ltd, if required.

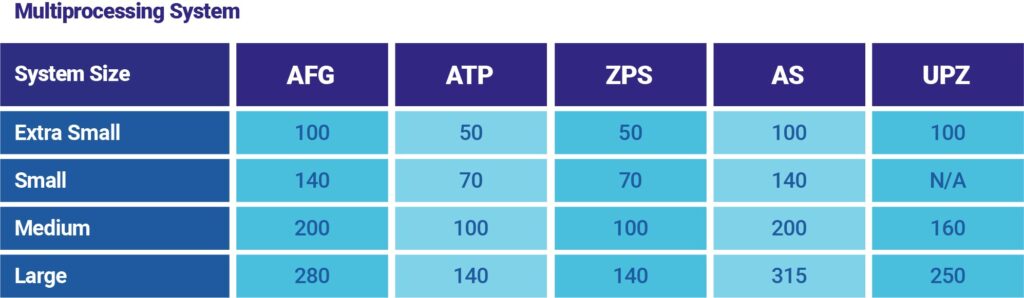

The innovative Hosokawa Alpine Multiprocessing System is an economical, compact and flexible multi-tasking mill for processing relatively small amounts of raw material and is currently available in a range of four sizes, which have been thoughtfully designed and engineered to accommodate up to five interchangeable milling and classification modules, which are also available in various sizes.

The Multiprocessing System’s five individual modules are based on size reduction equipment from our industry-leading milling and classification product portfolio: AFG Fluidised Bed Opposed Jet Mill, ATP Turboplex Ultrafine Classifier, Zirkoplex ZPS Classifier Mill, Spiral Jet Mill – AS Aeroplex and the Ultraplex UPZ Fine Impact Mill.

To view the technical details, applications and principles of operation for our collection of Hosokawa Micron Group milling and classifying equipment, including the full-size equivalents of the five Multiprocessing System modules, please click here.

Picoline – A Mini Multiprocessing System Solution

The Multiprocessing System is the ‘big brother’ of our unique Picoline laboratory equipment, which is an ideal benchtop solution for ultra-small batch and continuous processing of materials up to a few grams. The Picoline comes with a wide range of size reduction modules and accessories for wet and dry milling, mixing and particle design, with an integrated isolator solution available, if required.

Popular with an array of diverse manufacturing industries, research institutes and R&D departments, the Picoline is perfect for early-stage development of pharmaceuticals, chemicals, battery materials, foods, plastics, ceramics, functional materials and nanoparticles.

For further information about the Picoline, including technical details, functionality, accessories and system software, please click here.

Multiprocessing System Rental – A Tailor-made Hosokawa Micron Group Service

There are many reasons why you may wish to rent a Multiprocessing System direct from us, rather than purchase one: you may wish to test a small amount of product for only a few days; need a temporary solution to address a bottleneck in production or only wish to manufacture a certain product for a defined timescale.

With a Hosokawa rental solution – which can typically be fulfilled at short notice – you remain in complete control without having to invest and can adapt your production to customer demand very quickly.

We will supply, deliver, assemble, commission, maintain and clean your rented equipment and you can have peace of mind, knowing that the equipment is in Hosokawa Micron Group’s very safe hands. The equipment will be technologically up to date and ready to go and we can even supply trained Hosokawa Micron Group staff to operate the machine for you.

And it’s no problem if you decide you’d like to acquire the equipment at a later stage; just give us a call and we will be happy to provide you with an offer.

For further information and advice about renting a Multiprocessing System or other piece of Hosokawa Micron Group equipment, feel free to get in touch on +44 (0)1928 755100 or complete our short enquiry form – we would be delighted to help.

The Hosokawa Alpine Multiprocessing System has been specifically engineered to address the R&D requirements of sectors such as Pharmaceuticals, Chemicals, Food and Beverage, Minerals, Ceramics and Metals. This convenient multi-tasker provides a flexible way of helping companies to develop new powder-based products on a relatively small scale while also defining the optimal manufacturing process, allowing R&D teams to exchange up to five specialised milling and air classification modules into and out of the main system, which also incorporates the standard components of a piece of milling or classification equipment. Typically, the Multiprocessing System handles up to several kilograms of material per hour

Example applications include protein-enriched flour, plant-based proteins derived from cereals, pulses, algae, mushrooms, insects, seed oils etc, highly potent active pharmaceutical ingredients (HAAPI) and excipients, ceramic powders for the dental industry, homeopathic and nutraceutical powders, dry powder cell culture media, inhalants and Amoxicillin for the pharmaceutical sector, lactose for use in the food and confectionery industries and rare earths for the metal and mineral sectors.

Hosokawa’s uniquely designed Multiprocessing System is a versatile and compact milling and classification solution that is made for research and development, as well as small-scale powder production, using up to five easily exchangeable milling and classification modules. Larger production-scale Multiprocessing Systems, however, can also be supplied.

The main piece of equipment is fitted with all of the necessary general components required for grinding and classification – such as a frame, dosing facility, fittings, separator filter, blowers, a state-of-the-art control system and so on. Accessorising the main unit is the range of five modules, which can easily and conveniently be exchanged in just a few minutes to provide a host of different grinding and classification options and results.

To suit criteria such as batch size, product throughput, process gas volume flow etc, the main processing system and the modules are available in various sizes and capacities and we would be happy to advise on the most suitable solution for your needs. For more information, please refer to the Specification section.

The multi-tasking Multiprocessing System excels by offering a spectrum of milling technology within one piece of equipment. Each of the system’s five milling modules are a small version of a full-scale piece of Hosokawa-brand milling and/or classification equipment.

Below, we have provided an overview for each module, but more comprehensive details of the full-scale equipment each module is based on can be found on its dedicated product page.

AFG Fluidised Bed Opposed Jet Mill

A revolutionary opposed jet mill first introduced to the powder processing market over forty years ago, the AFG has quickly become a global milling star for Hosokawa Micron Group, with an excellent reputation for producing the highest quality of contamination-free, ultrafine powders from thousands of soft to very hard raw materials, including those that are heat-sensitive, magnetic, composite or abrasive.

Hosokawa Micron Group is the pioneer of jet milling and has amassed an enormous amount of technical expertise and experience collaborating with customers over the years. We are constantly refining and improving the technology behind the AFG mill, with important developments in areas such as energy-efficiency and more flexible capability to meet evolving industry needs that can benefit an increasing number of manufacturing industries.

Perfect for: Materials up to Mohs’ hardness 10 and fineness levels from 40µm to 2µm (AFG 100 model)

For further information, please click here.

ATP Turboplex Ultrafine Classifier

The ATP is an excellent classifying option when ultrafine powder is paramount, such as those required by the cosmetics, pharmaceutical and chemical industries. Engineered to be as versatile and robust as possible, the ATP’s capacity for very tight processing tolerances means it can accurately and efficiently eliminate oversized particles to achieve ultrafine, high-quality powder from all kinds of raw materials, including those that are traditionally difficult to process, including very abrasive material.

The classifier uses an adjustable, horizontally arranged classifier wheel and centrifugal force to extract the fine material from any remaining course material and offers a very high throughput solution.

Perfect for: Materials up to Mohs’ hardness 10 and cut point range from 120µm to 2µm (ATP 50 model)

For further information, please click here.

Zirkoplex ZPS Classifier Mill

Ideal for chemicals, minerals, powder coatings, food, toner and agrochemicals, the energy efficient Zirkoplex ZPS is a globally trusted, versatile piece of size reduction and classification equipment in one, which is used by many industries and can easily process soft raw materials, including adhesive products that tend to deposit.

The Zirkoplex ZPS offers a number of excellent features that preserve product integrity and hygiene, such as cool grinding, a gentle processing action and an easy-to-clean design. The mill is ATEX-certified and produces consistently high-quality results using an impact beater and classifier wheel. For abrasive products, a wear-protecting ceramic coating can be applied to the milling and classifying elements.

Perfect for: Materials up to Mohs’ hardness 3.5 and fineness levels from 8µm to 120µm (ZPS 50 model)

For further information, please click here.

Spiral Jet Mill – AS Aeroplex

Extremely popular with the pharmaceuticals industry for the production of antibiotics and for producing fine-grade chemicals from dry raw materials with a brittle, crystalline structure, the AS Aeroplex Jet Mill is ideal for producing contamination-free powder where high demands are placed on purity and fineness levels.

Laval nozzles tangentially inject grinding air into the equipment and cause the air to spiral in the high-pressure grinding zone. Feed material is introduced close to the nozzle, causing it to be repeatedly intercepted and processed by the air. Successfully milled material and air conveys to the discharge during the classification process, while any coarse particles remain in the mill until they are sufficiently reduced for successful classification. Different nozzle angles contribute to the fineness of the processed material, along with the amount of material introduced into the equipment at one time. Air flow is the critical common denominator, with a reduced centrifugal force (caused by a greater amount of product) resulting in a coarser result.

Perfect for: Materials up to Mohs’ hardness 3 and fineness levels from 5µm to 30µm (AS 100 model)

For further information, please click here.

Ultraplex UPZ Fine Impact Mill

Ideal for wet, dry and cryogenic milling, the specialist Ultraplex UPZ is impressively versatile and adaptable and is particular popular with our customers in the fields of pharmaceuticals, chemicals, minerals, food and animal feed. Offering interchangeable milling elements, the fineness of the powder or granules produced is determined by the chosen milling element and the speed of the mill, which can be adjusted. Apart from the Ultraplex UPZ’s ability to handle such a wide range of wet or dry raw materials, many challenging materials benefit from the Ultraplex’s cryogenic milling capabilities, meaning tough, elastic, heat-sensitive products, as well as those that are at risk of oxidisation or dust explosion can be effectively handled. For wet processing, we can supply a specially designed mill.

The fine impact mill is designed to meet the latest ATEX and cGMP standards for food and pharmaceutical production.

Perfect for: Materials up to Mohs’ hardness 3.5 and fineness levels from 5mm to 50µm (UPZ 100 model)

For further information, please click here.

The Hosokawa Alpine Multiprocessing System can accommodate no fewer than five exchangeable milling and classification modules, thanks to its thoughtfully designed construction and functionality – with component modules available for ultrafine air classification, fine impact milling, opposed jet milling, spiral jet milling and impact milling with classification. It may be supplied as an individual piece of equipment but can also be supplied as part of a larger bespoke process system, depending on your requirements.

For example, we have the expertise to supply the Multiprocessing System with an integrated Hosokawa Micron-brand isolator, tailor-made especially for your needs and to meet the latest safety criteria for your industry. Isolators not only address the risks to equipment operators associated with handling toxic or dangerous substances, but in the case of an aseptic isolator, also offer an essential solution to protect sensitive materials from the surrounding environment, thus maintaining the sterility of the material as it processes into powders or particles.

Trusted throughout the world by leading manufacturing companies spanning a wide variety of sectors – from pharmaceuticals and chemicals to cosmetics, food, minerals and ceramics – Hosokawa Micron Group is known for equipment innovations and game-changing processing techniques, which are complemented by a first-class in-house project management and engineering service – from initial design conception to equipment delivery and commissioning.

Our equipment portfolio is underpinned by extensive lifecycle management services and friendly, efficient customer care to support you during the decades of service you can expect to enjoy from Hosokawa Micron Group equipment and process systems.

Our high-performance Multiprocessing Systems are often purchased by existing clients as a complement to their full-size Hosokawa-brand milling and classification equipment. It’s an easy way for them to have the autonomy to develop and refine existing products or create new ones, as well as produce limited amounts of powdered products, knowing that accurate scale-up can be achieved quickly and easily if and when they are ready to go into full production.

One of our French food manufacturer customers uses a Multiprocessing System to help them innovate plant-based, protein-rich ingredients made from diverse raw materials such as cereals, pulses, seed oil, algae, microorganisms and even insects. As the global trend for consuming less meat shows no signs of abating, ‘protein-shifting’ has become one of the major development revolutions in food production as manufacturers tap into the growth potential of sustainable, protein-rich food and feed ingredients.

Knowing Hosokawa Micron Group is a world market leader in dry and wet powder processing techniques and equipment, our client came to us in the hope of being able to find an innovative, reliable and scalable processing solution for their R&D requirements.

Our high-performance Multiprocessing System – incorporating two kinds of jet mill, a classifier mill, fine impact mill and ultrafine classifier – has provided an excellent all-round solution for protein-shifting processes, offering just the kind of technical capability, flexibility, energy-efficiency and diversity required to sustain the successful development of raw materials that are sometimes technically tricky to process.

Using their Multiprocessing System, in collaboration with an existing Hosokawa-brand Zig Zag Classifier, means that our client can research a complete production process, from dehulling raw seeds, finely milling and then classifying to ultrafine particle size the resulting protein-enriched flour. The Multiprocessing System successfully separates the protein-starch agglomerates in the flour without destroying the starch particles in the process, using the Zirkoplex ZPS Classifier Mill module. For an even more refined result, the AFG Fluidised Bed Opposed Jet Mill would be the perfect solution.

Utilised by a wide range of industry sectors, from pharmaceuticals, chemicals, plastics and ceramics to food and nutraceuticals, the Multiprocessing System is adaptable enough to provide a plethora of small-scale development opportunities for many applications.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on