The in-demand Cyclomix is a specialist high-shear impact paddle mixer, principally designed and engineered by Hosokawa Micron for the intensive high-speed batch blending of potentially challenging cohesive, sticky and heat-sensitive powders – either together or with the addition of various liquids, pastes, slurries and melt binders –producing temperature-controlled perfectly homogenised powder products of the highest quality.

Additional processing capabilities of this robust multi-functional equipment include powder coating, metallic bonding, particle rounding, powder densification, product deagglomeration, plus heating, cooling and low-temperature vacuum drying (with liquid recovery) of many materials, ensuring the Cyclomix’s consistent popularity with diverse manufacturing sectors, including the highly regulated food, pharmaceutical, chemical and cosmetic industries.

Offered with an array of bespoke optional features and in a variety of sizes and unique designs – including hygienic, aseptic/sterile, vacuum/pressure and wear/corrosion-resistant – the mixer’s functional versatility, impressively short mixing times and relentlessly high levels of performance are enhanced by many standard features, not least the latest user-friendly process control technology, which is tailored specifically for your requirements.

For laboratory-scale high-shear batch mixing of cohesive powders with liquids etc up to 2 litres, we recommend our diminutive Mini Cyclomix model.

The innovative Cyclomix is an adaptable piece of high-impact batch mixing equipment, which is popular across the world for multiple applications that support diverse manufacturing sectors from pharmaceuticals to cosmetics, food to battery materials.

Perfect for blending challenging cohesive, sticky and heat-sensitive materials that require intensive processing and very high-quality homogenisation, the Cyclomix has several excellent features that set it apart, including uniquely designed components that enable multiple applications to be performed quickly and very accurately.

Standout features include combined high-shear and high-impact mixing, excellent temperature control, seals and bearings positioned above the product zone and a super-simple and highly efficient discharge system – utilising our specially designed ISEM ball segment valve – which guarantees optimal yield.

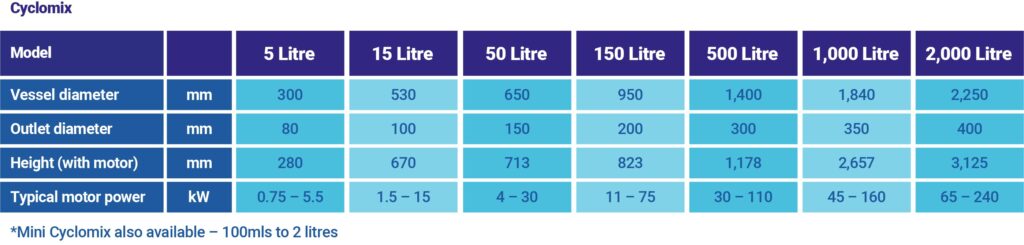

The Cyclomix range is available in a comprehensive number of models and tailor-made configurations, with capacities ranging from 5 litres to 2,000 litres for the standard Cyclomix. An example selection of sizes and specifications are detailed below.

Optional Features

Mini Cyclomix

Perfect for laboratory-scale use, the standalone Mini Cyclomix is based on the technology and processing principles of the full size Cyclomix range. Ideal for accurately blending DPI formulations for the highly regulated pharmaceuticals industry, the comparatively diminutive Mini Cyclomix features exchangeable processing bowls (100mls, 1 litre and 2 litres) and offers reproducible processing results, accurate temperature control (using a heating/cooling jacket), single layer coating of materials, rounding off and densification of particles, as well as high-quality homogenous and lump-free mixtures.

As with the standard version, most of the energy used to facilitate the processing is generated by the configuration and close positioning of the internal paddles in relation to the conical vessel wall, the high-speed rotation of the paddles and the addition of a high-quality blade, making it a very efficient high-shear blender. Full discharge is achieved by our unique, centrally located, ISEM ball segment valve.

For the handling of hazardous or potent materials, off-line filling and discharge can be achieved by the integration of a Hosokawa Micron Ltd containment isolator. Sterile/aseptic and CIP/SIP designs are also available.

We would be delighted to advise and support your projects that may require reproduceable process up-scaling from the Mini Cyclomix to a production-scale Cyclomix.

Modulomix

The compact Hosokawa Micron Modulomix is a continuous modular paddle mixer for laboratory-scale use, based on the well-proven Cyclomix batch mixing concept. Originally designed for the pharmaceutical industry, it is also suitable for the food, chemical, mineral and metal industries and provides high-, mid- and low-shear processing capabilities at high speed for fine and cohesive powders.

Extremely versatile in its application range – from coating, sterilising, agglomerating and de-lumping, to dry powder mixing, hydrating challenging powders and crystallising – the Modulomix is easy to clean and maintain, and can typically process 2.5kgs to 10kgs of material per hour.

For further information and advice on our Mini Cyclomix or Modulomix high-impact mixing equipment, please feel free to get in touch with us via our Enquiry Form or by telephone on +44 (0)1928 755100.

Contract Manufacturing and Product Testing Services

Hosokawa Micron Ltd is able to organise and facilitate in-house contract manufacturing and product testing services at our sister company’s state-of-the-art 2,000m2 Hosokawa Micron Test Centre facility, based in the Netherlands, which is the only one of its kind in Europe and one of only a handful in the world.

Offering a comprehensive and representative selection of Hosokawa-brand powder and particle processing equipment and process systems – including three Cyclomix high-shear batch mixers (5 litres, 50 litres and 500 litres) – you can take advantage of our extensive powder and particle processing expertise, whether for one-off or rolling contract manufacturing projects or for R&D and product testing purposes to establish the optimal performance, processing techniques and model required for your new Hosokawa Micron Cyclomix equipment or process system.

We can help you to launch your new products, develop your processes, fill the production gap prior to the arrival of your new equipment, produce materials for marketing purposes and produce small quantities of products to help define the correct specification for your Cyclomix.

Conveniently, we can now offer customers remote attendance opportunities for contract manufacturing or product testing and R&D runs, if required, using our video link service. Of course, we are also more than happy to continue to welcome our customers in person, if preferred. Please contact us for further information and availability

The Cyclomix offers intensive, paddle-style, thermal mixing and agglomeration of fine cohesive and/or sticky powders, slurries, pastes, liquids and melt binders. The expertly engineered technology and design of this high-shear batch mixer gives great versatility in application and is widely used by a variety of processing industries – such as the pharmaceuticals, chemicals, minerals, food and beverage, nutraceuticals and cosmetics sectors – who choose the Cyclomix for its multi-purpose capabilities, high performance, impressive processing speed and reputation.

Typical materials the Cyclomix can process include waxes, hormones, excipients, pigments, magnetic materials, dental compounds, active pharmaceutical ingredients (APIs), mica, bentonite, pigments, lactose, proteins, catalysts and plastics, but there are many, many more.

In addition to low- or high-speed mixing and agglomeration, the Cyclomix is able to coat powders with other powders and liquids, perform particle spherization tasks, densify powders, offer low temperature vacuum drying and liquid recovery, bond metallics in powder paints, grind and de-agglomerate, disperse pigments, instigate chemical reactions, heat and cool materials, as well as agglomerate using moisture or heat.

*Mini Cyclomix – 100ml, 1 litre and 2 litre exchangeable bowls

The highly regarded Hosokawa Micron Cyclomix offers high-speed, intensive batch processing of challenging cohesive powders and heat-sensitive materials with a low melting point, and can effortlessly mix powders with liquids, mix wet powders together and mix and disperse pastes and slurries. Additional processing capabilities include coating, spherization, particle design, heating and cooling materials, vacuum drying and de-agglomeration.

The Cyclomix’s versatility is underpinned by its uniquely engineered, patented processing technology, including a conical-shaped mixing vessel, featuring specially designed and configured paddles, an impact blade and a domed cover for highly efficient homogenisation of materials in the quickest time possible.

Product enters the widest part of the domed mixing cone from the top and drops downwards to the narrowest part of the cone. The Cyclomix’s cantilevered central rotor is driven from the top and operates a series of paddles that are specially positioned inside the cone, close to the vessel wall, to create an upward and downward flow in sequence.

The uppermost paddle is the largest and has a tip speed of up to 30 metres per second. This paddle configuration allows for optimal acceleration of the processing material, which centrifugal forces move upward and outwards against the interior of the vessel wall in a spiral movement. As the rotor is driven from the top, no seals or bearings come into direct contact with the product zone.

Strong frictional forces are generated by the paddles, assisted by the increasing rotor diameter as the cone widens. When the material reaches the top of the Cyclomix’s mixing vessel, it enters the vessel’s domed area, which deaccelerates the material and drops it downwards towards the centre of the cone, where a rotating blade, positioned just below the domed area, provides additional impact and shear forces, dispersing and agglomerating the cohesive powder (and any other material) as it falls and continues to circulate and quickly blend.

The combination of the Cyclomix’s unique engineering, the processes of accelerating and deaccelerating the material while it moves up and down in the cone, the shearing forces created by the paddles and the particles themselves and the very efficient blade ensure super-quick, high-impact mixing, resulting in perfectly homogenised, high-quality end products.

An optional heating/cooling jacket is available for intensive thermal mixing, with temperature-controlled heat transfer between the jacket and product, enabling accurate and effective heating and cooling of products including melt binders and wet agglomerates.

Discharge of the blended product is effortless, impressively thorough and quick, thanks to the centrally located outlet and our unique ISEM ball segment valve, positioned at the narrowest point of the conical vessel’s cone, which also ensures a maximum yield can be consistently achieved.

Hosokawa Micron’s Cyclomix high impact batch mixer can be supplied as an individual piece of equipment but can also be supplied as part of a larger, Hosokawa Micron-designed, process system, combining multiple ancillary equipment.

Depending on the application and requirements of the material, ancillary components for a process system might include a pump, flow sensor, dosing pump, retractable cleaning nozzle, charging hopper, contained filling drum, split valve, end product drum filling, mixer lift, HEPA filter, electric air heater, pressure sensor, powder and liquid dosing, sampler and a control system with cabinet, all of which Hosokawa Micron can supply and fit.

Conveniently, the Cyclomix is available in a comprehensive range of sizes and bespoke designs to address the requirements and concerns of highly regulated sectors, such as the food, chemical and pharmaceutical industries. As such, we can offer hygienic, vacuum/pressure, sterile/aseptic and wear/corrosion options, along with high-performance containment equipment, such as a tailor-made isolator, which can be designed, engineered and built in-house by Hosokawa Micron Ltd.

In addition, Hosokawa Micron Ltd is proud to have the expertise to offer additional services, such as custom-made state-of-the-art process automation, as well as a comprehensive qualification service, where we will provide an in-depth analysis of factors such as your production processes, as well as environmental, safety and supply chain considerations. This is instrumental in determining the optimal solution for not only the equipment or process system itself, but the environment it will be housed and operating in.

Trusted throughout the world by leading manufacturing companies across multiple sectors and disciplines, we are renowned for innovating ground-breaking processing techniques, high-performance equipment and complex process systems to manufacture and handle bulk and small batch powders, particles, liquids, vapours and multiple raw materials.

Our equipment and powder processing systems expertise, which spans more than a century, is underpinned by a first-class in-house project management and engineering service – from initial design conception to equipment delivery and commissioning – thereafter supported by extensive lifecycle management services and aftersales customer care to support you during the decades of service you can expect to enjoy from Hosokawa Micron Group equipment and process systems.

The Cyclomix is the high-impact batch mixer of choice for high-profile cosmetics companies the world over. Perfect for efficiently manufacturing premium-quality face powders with complex formulations that meet the demands of the industry and the end user, the Cyclomix produces perfectly blended, lump-free batches of consistently coloured and textured fine powder by continuously spraying liquid from its central spray nozzle into the conical mixing vessel. The colour pigments are thoroughly dispersed in the vessel without over-wetted the powder mixture, which overcomes any need for further milling of the powdered material.

Pressed metal powders are used extensively for products such as automotive gear wheels, power tools, small domestic appliances, locks and pumps. The Cyclomix is the ideal solution for introducing a binder to a metal powder mixture prior to pressing or sintering. The batch mixer also excels when creating uniform coatings on metal powder particles, including coatings of oil for preventing oxidisation and coatings of wax to ease the release of metal ingredients from moulds.

Dry powder inhalers (DPIs) containing very fine active pharmaceutical ingredient powders are increasingly popular for delivering respiratory drugs to help treat illnesses such as asthma and even diabetes. Fast absorption of the medicine can be critical, particularly in the case of asthma, so formulation quality is key.

Active ingredients are mixed with an excipient, such as lactose, which provides cohesion in the inhaler and separation of the API and excipient when it reaches and is absorbed by the lungs. These exact characteristics require highly specialist processing for the inhaler to perform to optimal levels.

This is where the Cyclomix is a particularly useful solution, as it can exactly blend the small amounts of APIs and large amounts of excipients so that the active ingredients in the dry powder mixture are successfully and fully released when inhaled. Low mixing energy is required for this purpose, which the Cyclomix can achieve, eliminating the risk of particle erosion and a poor-quality product. The Cyclomix can also densify APIs prior to them being made into pills.

When making high-quality printer toner, the Cyclomix blends dried cohesive toner powder with flow-adding and charge-controlling agents, using high-shear forces to coat the toner particles with the additives and provide powder with excellent flow properties and optimal conductivity behaviour for the printer. A cooling jacket prevents the mixture from heating up as it is blended. Similarly, the Cyclomix is often chosen to coat various chemicals used in fire extinguisher powder.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on