Perfected in collaboration with customers from a variety of manufacturing sectors to address the increasing need for finer and finer powder in the range of 10µm to 500µm, the classic Hosokawa Alpine Contraplex fine impact pin mill has undergone an enhancing technical and ergonomic transformation that promises to set it even further apart from its competitors.

The upgraded Contraplex CW II is now much more energy-efficient and even better for prolonged, trouble-free continuous operation. The tailor-made compact mill has been specifically optimised to overcome the complexities of the most challenging applications and materials, such as the disintegration of powders for sharper and cleaner protein-shifting, cryogenic milling for pharmaceutical APIs and culinary spices etc, plus the intensive, agglomerate-free mixing and grinding of two or more products.

Extremely user-friendly, the practical mill is equipped with a generously sized mill door, a wide chamber housing and two very high-speed pin discs that can gently and deftly handle hundreds of products with problematic characteristics – including heat-sensitive, oily, fatty, brittle, moist, hygroscopic, crystalline and sticky materials that might normally be prone to degrading and/or depositing during processing. Special designs can be tailor-made for pharmaceutical and coating powder manufacture.

Hosokawa Alpine’s versatile Contraplex CW II is available in a variety of useful sizes, is purpose-built for longevity and will provide a reliable, safe, flexible, efficient and consistently superlative performance. Importantly, the equipment incorporates a cast stainless-steel housing that is both explosion-proof and shock-resistant to the latest ATEX standard to increase operator and plant safety against potential dust explosions.

The latest generation Contraplex CW II fine impact mill by Hosokawa Alpine is a definite improvement on the tried and tested classic Contraplex milling range. The advanced new version is at least 10% more energy-efficient, thanks to enhancements such as its improved drive concept, and offers a multitude of exciting technical and mechanical innovations that set the mill apart.

Clever new features and capabilities include higher milling speeds for even finer-grade milling, improved grinding chamber accessibility for easier cleaning and maintenance, a polished infeed with a larger minimal cross-section, low porosity cast stainless-steel housing, no dead spaces in the purge air system, an aerodynamic and optimised shape, a gearless mill drive, a cold-protected bearing for operational longevity, relative speed of outermost pins up to 240 m/sec, the same motorisation and speed ranges on the door and housing side, as well as easy gap adjustment via a door-side bearing.

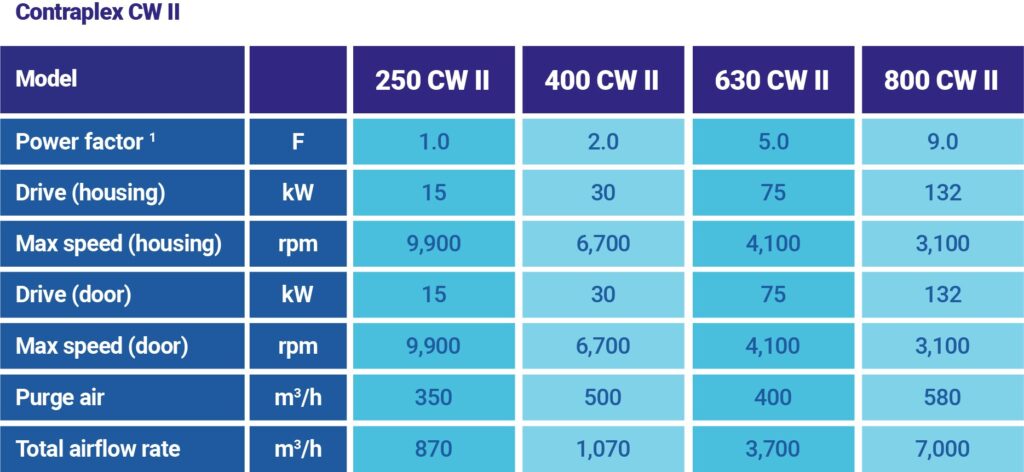

Tailor-made for your specific needs and the requirements of your industry – including the stringent standards of the food and pharmaceutical sectors and European safety guidelines – the Contraplex CW II fine impact mill range is currently available in four sizes (250 CW II, 400 CW II, 630 CW II and 800 CW II) and can be manufactured with special design features, if required.

Special Design Features

Optional Designs and Features

In-house Test Centre Research and Development

Whether it’s a foodstuff or a pharmaceutical excipient, mineral, protein or materials such as synthetic rubber, wax, explosives, dyes, pigments, resins and plastics, by working in collaboration with each customer, we can exploit the full-size sample milling equipment and process systems permanently housed in our dedicated Test Centre in Germany, which is one of the world’s largest and includes an array of equipment and ancillaries from our product portfolio, including examples of the Contraplex CW II 250.

Here, we refine or devise from scratch the optimal processes and most suitable Hosokawa-brand milling equipment required for creating the highest quality powdered raw materials.

Applications are rigorously put to the test and equipment is configured, refined and optimised to meet your specific needs and that of your raw materials, either at laboratory or production scale. Every stage is thoroughly documented and samples provided to provide important information critical for decided which is the optimal high-performance processing solution for your project.

Our latest technology is underpinned by the wise advice and in-depth knowledge of our highly experienced in-house engineers and scientists, who have vast experience of working with literally hundreds of diverse (and sometimes very challenging) materials.

For further information and advice on our Contraplex CW II fine impact milling equipment or to arrange for your product and application to be trialled by our innovative processing equipment and systems, please feel free to get in touch with us via our Enquiry Form or by telephone on +44 (0)1928 755100– we would be delighted to help you choose the best milling system for your needs.

Picoline – Picocross module for fine impact milling ultra-small amounts of raw products

For benchtop laboratory-scale research and development, Hosokawa Alpine’s multi-tasking Picoline features a collection of interchangeable modules to perform various small-batch processes, including milling, mixing, classification and particle design.

Included in the module range is the Picocross, which is a tiny version of the Contraplex CW II fine impact mill for processing very small amounts of dry soft to medium-hard raw materials. The design and principle of operation is virtually identical to that of the full-size mill, helping to facilitate accurate scale-up of processes and establish end product quality criteria to production scale.

For further information, please click here.

Originally designed to transform cocoa into powder but now considered to be the food industry’s classic spice mill, the new Hosokawa Alpine Contraplex CW II range has been reconsidered and reengineered to offer an even more technology-laden, innovative and optimised solution for the continuous fine milling of multiple raw materials, including those that are brittle, crystalline, moist, greasy, hygroscopic or adhesive in nature and have a maximum Mohs hardness of 3. The size reduction equipment may also be used to perform cryogenic milling tasks using liquid nitrogen, which is ideal for heat-sensitive or oily materials such as spices.

Developed in close collaboration with our customers, the latest incarnation of the well-regarded pin mill produces even finer powders than its predecessor and can be customised to perform the most challenging processing tasks, including protein shifting, milling polymers for 3D printing powder and coating fillers. The equipment can also successfully achieve extended production times, which is ideal for notoriously difficult oily and fatty materials.

Additional materials that benefit from the fine grinding performance of the Contraplex CW II include mineral powders, vitamins, pharmaceutical excipients, active pharmaceutical ingredients (APIs) lactose, tea leaves, seaweed, chocolate crumb, animal feed, collagen, herbs, soy protein, potato starch, corn starch, wax, explosives, berry seeds, gelatine, Arabica coffee beans, plastics, pesticides, organic and mineral pigments, natural and synthetic rubbers, dyes, phosphates, yellow peas, oat flakes, sesame seeds, hemp seeds, coriander, cloves, almonds, chocolate crumb and fish meal.

The Hosokawa Alpine Contraplex CW II is a high-performance fine impact pin mill for continuous use. It has the ability to process a wide range of raw, often challenging, materials up to a Mohs hardness of 3 (or contaminations less than 0.1%) into very fine, contamination-free, powders in the range of 10µm to 500µm.

Material feeds into the centre of the mill, where it is processed and normally discharges from the bottom outlet. However, the mill can be configured with a tangential direction discharge, upon request.

Central to the Contraplex CW II’s performance is the mill’s two adjustable, counter-rotating opposing pin discs – positioned on the door side and the machine side. The discs are driven at extremely high speed, more so than can be achieved by a single pin disc (such as the one that can be supplied as an interchangeable milling element for our alternative fine impact mill, the Ultraplex UPZ).

Conveniently, the pins are available in a standard special steel, as well as alternative materials that meet the highest requirements for hygiene, wear and contamination.

The unique Contraplex CW II’s pin discs can operate at speeds up to 240m/sec at the outermost rows of pins, which is perfect for processing brittle materials, but may be adjusted to operate at lower speeds to micro-manage the fineness of the processing material.

The strong centrifugal force created in the mill’s comparatively oversized chamber housing ensures that even moist, greasy, sticky and hydroscopic material can be homogeneously processed with ease without forming deposits on the pins and in the grinding chamber, which would, undoubtedly, affect the mill’s performance. In addition, liquid nitrogen can be introduced to permit cryogenic milling of heat-sensitive materials such as spices.

The mill’s high-performance belt-driven motors allow for optimum configuration of the transmission ratio for both the process and the product. In turn, this facilitates a more energy-efficient operation as the motor and rotating pin disc work together more effectively.

The ability to set the rotational direction and disc speed of the pin discs and adjust the air flow and feed rates increases the opportunities to process a wider range of materials, including notoriously tricky heat-sensitive ones, while the mill can also homogeneously mix and grind two or more materials, which is an added benefit of the Contraplex CW II.

A premium-quality monitoring system for the mill’s two bearing units ensures that temperature and vibration levels can be continually assessed, giving the opportunity for immediate preventative maintenance, if needed. Rinsing air (automatic intake or forced rinsing) stops the product from entering the bearing units and stops any processing material from depositing behind the pin discs, which helps to maintain the mill’s excellent performance. The permanently lubricated bearing units are identical and, when necessary, are easy and quick to change.

Conveniently, the mill’s generously sized door is specially hinged for maximum accessibility and to aide effective cleaning and maintenance.

Cryogenic Milling of Spices

The Contraplex CW II is the perfect solution for the cryogenic fine milling of problematic raw materials such as spices, which are often heat-sensitive, moist and packed with essential oils and fats that tend to make them greasy.

Well-known in the global food industry as the classic spice mill, the Contraplex CW II overcomes the challenges of handling spices effectively by using a cold milling technique to achieve the highest-quality results – even in prolonged, continuous use.

The excellent performance of the pin discs and an oversized grinding chamber, along with the addition of a cooling agent such as CO2 or LN2, ensures that the grinding process is trouble-free and intense, yet gentle, while the temperature is cool enough to preserve the spices’ fats and essential oils (typically to around 97%), producing a very fine, excellent-quality end product that is more aromatic and flavourful than spices processed at an ambient temperature, where the loss of essential oils could be as high as 43%.Both the product and the process system are usually cooled by direct injection of the cooling agent into the mill. Alternatively, if longer residence times or lower temperatures are required, the raw material can be precooled and embrittled in a Nauta® Conical Screw Dryer prior to milling.

A combination of considered equipment engineering and cryogenic milling factors conspire to ensure the Contraplex CW II range is the ultimate solution for grinding spices – with throughout almost twice as high as that achieved by traditional ambient processing methods and the risk of fire eliminated, while the chance of the mill clogging up by the melting of the fats in the spices is virtually none. Process control can also be optimised, to ensure a consistently high performance and excellent-quality end products.

Other materials that benefit from cryogenic milling techniques include almonds, coffee beans, pharmaceutical APIs and polymers such as polyamide (nylon) and elastomers such as TPU (thermoplastic polyurethane).

Process System Solutions

The high-performance Hosokawa Alpine Contraplex CW II can be supplied as an individual fine impact pin mill but may also be supplied as part of a complex, tailor-made process system, integrated with additional components and equipment such as a Nauta® Conical Screw Dryer, ATP Turboplex Ultrafine Classifier or Zirkoplex ZPZ Classifier Mill, blower, product tank and state-of-the-art control system.

Suitable for the requirements of various manufacturing sectors, tailor-made Contraplex CW II milling systems are particularly popular with the pharmaceuticals, minerals, chemicals, food and beverage, cosmetics and recycling sectors, offering versatile processing capabilities and efficient processing of a wide spectrum of straightforward and very challenging materials into fine, agglomerate-free, powder of supreme quality.

High-performance process systems for a challenging raw material – soybeans

Working in collaboration with our global food processing client, Farmesa, our goal of creating a technically and ergonomically improved milling process system for the notoriously difficult-to-process soybean has been realised.

Reliable, flexible and engineered to meet and even exceed the highest safety and hygiene standards, the centrepiece Contraplex CW II – working in tandem with a Hosokawa Alpine Zirkoplex ZPZ Classifier Mill and additional milling system components – has been instrumental in fulfilling the shape-shifting requirements of the, increasingly important, soy processing market, producing a very fine, dry and pure powder from an oil-rich, full fat raw material. Overcoming this particular challenge has added yet another dimension to the specialist milling equipment in our product portfolio.

Of course, soybeans are just one of the challenging materials that can effectively be processed by our milling and classifying equipment. Almonds and Arabica coffee beans are two more examples of foods that can be difficult to process to a high enough quality due to their challenging attributes. Cryogenic milling, which can be undertaken by a Contraplex CW II process system, is the ideal method of overcoming any potential degrading of the heat-sensitive raw materials while they are processing.

Hosokawa Micron Group – Complete lifecycle solutions for manufacturing high-quality powder

Trusted across the globe by world-leading manufacturing companies, Hosokawa Micron Group is best known for its pioneering equipment innovations and game-changing powder processing techniques. These innovations are complemented by a first-class in-house project management and engineering service – from feasibility studies, product testing and initial design conception to equipment delivery, commissioning and maintenance.

Our powder processing equipment portfolio is underpinned by extensive lifecycle management services and friendly, efficient customer care to support you during the decades of service you can expect to enjoy from Hosokawa Micron Group equipment and process systems.

The Contraplex fine impact mills have been making waves in the food and beverage industry for decades and are considered to be the classic mill for problematic spices that are adversely affected by the addition of heat during processing and have a very high oil content that make them greasy and traditionally hard to process successfully.

Thanks to its ability to cryogenically mill, the new and improved Contraplex CW II is now even better at handling these types of challenging foodstuffs, retaining their fragrant essential oils by up to 97% and preserving their fats to produce more flavourful and aromatic spice powders of a much higher quality than ambient processing can achieve.

Difficult-to-process crops such as oli-rich soybeans are also ideal candidates for high-quality processing by the Contraplex CW II.

With vast experience in the field of food processing, Hosokawa Micron Group is a world-leading ‘go-to’ supplier of high-performance milling and classifying equipment. We have been able to harness our in-depth knowledge of processing a huge array of raw ingredients – from the softest berries to the hardest, most oily seeds and spices – to overcome the challenge of creating a very fine dry powder from an organic raw product that has a high oil content and, while being processed, poses a serious dust explosion risk.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equ