Hosokawa Alpine’s adaptable Bexmill ABM cone mill is perfect for demanding multi-application processing of a wide variety of raw materials with various characteristics – either sticky, moist or dry, soft to medium-hard. The crushing equipment is particularly popular throughout the highly regulated pharmaceutical, chemical and food sectors, which benefit from our wide-ranging powder processing expertise and innovative bespoke equipment and system designs that fully meet ATEX, FDA and cGMP standards.

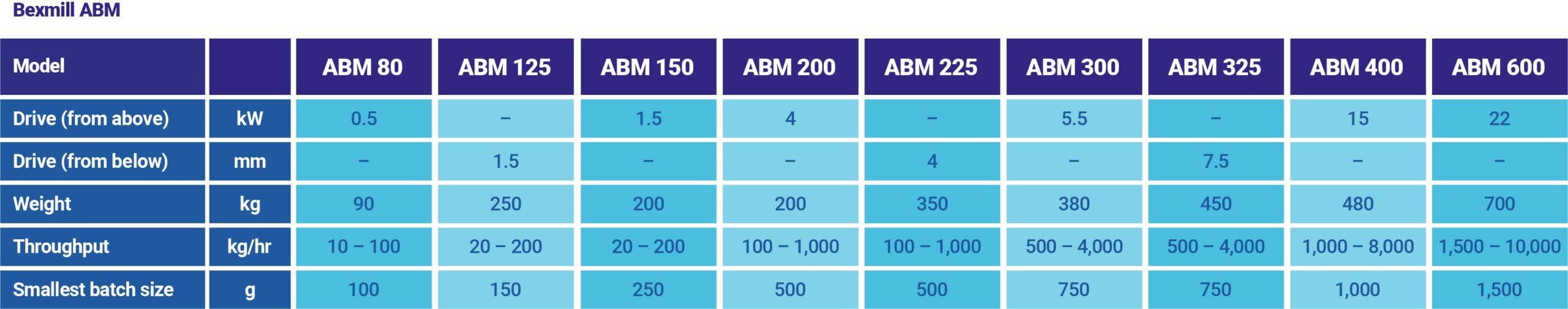

Conveniently, the Bexmill ABM range is available in many sizes and different configurations. The largest model in the cone mill’s range is capable of throughputs of up to ten tonnes per hour, while the smallest model can process batches as little as 100 grammes, which is ideal for small-scale laboratory and R&D purposes.

The Bexmill ABM’s impressively diverse capabilities, specifically tailored processing solutions, thoughtfully engineered design features and unique optimised interplay between the grinding tool and perforated screen in the conical-shaped grinding chamber ensure optimal energy efficiency as it gently, quietly and quickly produces high-quality crushed material that is perfectly homogenised with a defined top cut, increased bulk density and better flowability with minimal fines.

The popular Bexmill ABM is Hosokawa Alpine’s multi-tasking, high-speed crushing technology for handling up to ten tonnes of moist, dry or sticky bulk material per hour. The energy-efficient, low-noise cone mill is designed to be operated in either continuous or batch mode and can accomplish a variety of size reduction tasks gently and effortlessly, including perfect homogenisation, improved flowability, increased bulk density and agglomerate dispersal.

Currently available in an impressive range of nine models, throughput per hour is determined by the size of the model chosen and ranges from between 10kgs and 100kgs for the diminutive ABM 80 to between 1,500kgs and 10,000kgs for the largest and most powerful model, the ABM 600.

The range is thoughtfully designed and engineered to be as adaptable as possible and offers a number of design options and component solutions to suit many different applications and industry sectors, such as a choice of four types of perforated screen (round, rasp-like, slotted or square) with a typical mesh size between 0.5mm and 10mm, a motor configured and driven from below or above (depending on the model chosen) and industry-regulated designs to conform to ATEX, cGMP and FDA standards.

The Bexmill ABM cone mill is easy to clean and operate and is also quick to maintain, with effortless exchanging of rotors and screens when required. Conveniently, the equipment does not require dedusting and feed material does not have to be dosed.

Accessories

Design Options

Test Centre Product Development Solutions

Hosokawa Micron Group is proud to be in a position to offer a comprehensive product trial service as part of the development of your application processes and equipment designs. The in-house service is backed up by the latest powder and particle processing technology and state-of-the-art digital support, which can be 100% online if an in-person visit to one of Hosokawa Micron Group’s Europe-based test centres or laboratories is not feasible.

Collaborating with your engineering team, our in-house team of expert technicians, scientists, engineers and operators will rigorously put your application requirements to the test to devise the optimal process system or piece of equipment.

We perform well in excess of 500 product trials per year, each one typically taking up to a week to complete, and, for your convenience, our team is available at all times during the trial process to assist you and answer any queries, either remotely or in-person at our facilities.

Product, application and equipment trials can be carried out at laboratory or production scale using our comprehensive suite of Hosokawa-brand powder processing and containment equipment, ancillary equipment and analytical instruments, and we provide full documentation, reports, test results and sample material throughout the process.

As one of the world’s leading powder processing specialists, Hosokawa Micron Group has more than a century’s-worth of in-depth knowledge and experience working with a huge and complex variety of materials and for a wealth of applications in increasingly diverse and exciting sectors.

Whether its traditional manufacturing industries such as pharmaceuticals, nuclear and food, or more contemporary sectors such as battery materials, recycling and advanced materials, we can test your products in a realistic environment to ensure you can achieve the largest, most high-quality yields from your raw materials prior to supplying your optimised equipment or system.

We have in-house test centres dedicated to food, particle and powder processing, recycling, granulation and compaction. Our set up also includes a pharmaceutical-based clean room featuring containment equipment, a circuit-air mode and an OEL < 10µm/m3, along with a fully equipped laboratory dedicated to particle analysis, rheological properties and microscopy.

From feasibility studies, process optimisation, scale-up and product development to special designs that meet challenges such as cryogenic milling, equipment for potentially explosive environments and products, abrasive and hazardous products, process simulation, clean room designs and particle size analysis – the possibilities and opportunities are endless.

For more in-depth information about Bexmill ABM cone mill and process system specifications, including full details regarding the complete range of accessories and design options available and our cutting-edge testing centre services, please feel free to contact us on +44 (0)1928 755100 or complete our short enquiry form – we would be delighted to trial your processes and materials and help you to choose the perfect milling equipment or process system for your application.

The Hosokawa Alpine Bexmill ABM range excels at gently grinding, de-agglomerating, homogenising and granulating a wide range of moist to dry coarse to medium-size materials – including those that are potentially explosive, have been roller compacted or are sticky in nature. From laboratory scale to bulk production levels of up to ten tonnes per hour, the versatile equipment is also very useful for applications such as post-mixing, improving the flow characteristics of powder, crushing rejects, post fluid bed and kiln drying and increasing the bulk density of powder.

Popular in the pharmaceuticals, chemicals and food industries – but also perfect for use by the cosmetics and soaps and detergent sectors – the cone-shaped mill can quickly and efficiently process diverse materials such as antibiotics, APIs, excipients, hormones, lactose, pigments, seaweed, spices, dried fruits, soya, oats, collagen, starches, salts, food seasonings, barley, bakery products, berry seeds, vitamins, sesame seeds, cellulose, milk powders and herbs.

Potentially explosive materials can be safely processed without issue thanks to special dust-tight and gas-tight ATEX designs, while pharmaceutical applications are covered by cGMP-standard hygienic designs and food-grade equipment is designed to meet the exacting approval of the FDA.

The Bexmill ABM cone mill is very popular in the food sector where it excels at adapting to a huge variety of raw materials, from medium-hard fruit seeds and spices to soft herbs and sticky potato starch.

The growing world population constantly elevates the requirement for milk powder suitable for high-quality baby formula. Special de-agglomeration processing is essential (after mixing and drying) to ensure the powder is suitably fine and free-flowing and this can be performed by the Bexmill ABM cone mill.

Hygroscopic products (such as salt and sugars) need to be handled carefully to achieve a lump-free consistency suitable for storage – homogenisation using a Bexmill ABM cone mill offers the optimal solution for meeting this requirement.

The Bexmill ABM cone mill is very popular in the food sector where it excels at adapting to a huge variety of raw materials, from medium-hard fruit seeds and spices to soft herbs and sticky potato starch.

The growing world population constantly elevates the requirement for milk powder suitable for high-quality baby formula. Special de-agglomeration processing is essential (after mixing and drying) to ensure the powder is suitably fine and free-flowing and this can be performed by the Bexmill ABM cone mill.

Hygroscopic products (such as salt and sugars) need to be handled carefully to achieve a lump-free consistency suitable for storage – homogenisation using a Bexmill ABM cone mill offers the optimal solution for meeting this requirement.

Bakery goods that have broken during the production process – such as salty snacks, sweet pastries and cookies – no longer need to be disposed of. Instead, they can be returned to the production line having been re-processed by the Bexmill ABM cone mill, saving costs and helping to avoid food waste.

The multi-tasking Hosokawa Alpine Bexmill ABM crusher can be supplied as an individual piece of milling equipment but may also be supplied as part of a larger, tailor-made process system designed, engineered and manufactured by Hosokawa Micron Group to precisely cater for your specific application and requirements.

Conveniently, the Bexmill ABM cone mill is custom designed to be compatible with a wide variety of upstream and downstream processing connections, which is ideal for integrating the mill into an existing process system.

Trusted by leading manufacturing companies spanning a wide variety of sectors – from pharmaceuticals and chemicals to cosmetics and food – Hosokawa Micron Group is known throughout the world for equipment and process system innovations to complement our game-changing processing techniques.

A first-class in-house project management and engineering service, along with technical services such as contract manufacturing, particle design and powder testing, offer you a complete, professional solution to match our adaptable high-performance products and the process systems that we can precisely tailor-make for you.

Our equipment portfolio is also underpinned by extensive lifecycle management services and friendly, efficient customer care to support you during the decades of service you can expect to enjoy from Hosokawa Micron Group equipment and process systems.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on